Unleashing the Future: How 4D Printing is Revolutionizing the Creation of Smart, Adaptive Materials to 4D Printing

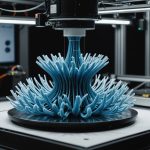

Imagine a world where materials can change shape, adapt to their environment, and perform complex functions over time. This is not science fiction, but the reality of 4D printing, a revolutionary technology that is transforming the way we design and use materials. In this article, we will delve into the world of 4D printing, exploring its principles, applications, and the immense potential it holds for various fields, including biomedical engineering, architecture, and more.

What is 4D Printing?

4D printing is an extension of the 3D printing technology, but with an added dimension: time. This means that 4D printed materials can change shape, properties, or functionality over time in response to external stimuli such as temperature, humidity, light, or pressure. The concept is inspired by natural examples like the pinecone, which opens its scales in dry conditions to release seeds and closes them in wet conditions to protect them[1].

Topic to read : Transforming airport safety: the game-changing impact of biometric verification on passenger security

Key Mechanisms and Materials

To create these smart materials, several key mechanisms and materials are employed.

Shape Memory Polymers and Hydrogels

Shape memory polymers (SMPs) and hydrogels are among the most commonly used materials in 4D printing. SMPs can revert to their original shape after being deformed when exposed to a specific stimulus, such as temperature or light. Hydrogels, on the other hand, are highly absorbent polymer networks that can swell or shrink in response to humidity, making them ideal for applications requiring dynamic shape changes[2].

Also to read : Transforming hearing aids with ai: discover how advanced algorithms elevate sound quality and user experience

Stimulus-Responsive Materials:

- Temperature: SMPs can change shape when heated or cooled beyond their transition temperature.

- Humidity: Hydrogels swell or shrink based on the moisture levels in their environment.

- Light: Certain polymers can change shape or properties when exposed to specific wavelengths of light.

- pH: Materials can respond to changes in the pH of their surroundings.

- Magnetism: Some materials can change shape or move when exposed to magnetic fields[2].

Applications in Biomedical Engineering

One of the most promising areas for 4D printing is biomedical engineering, where it is revolutionizing tissue engineering and the development of medical devices.

Tissue Engineering

In tissue engineering, 4D printed materials can mimic the natural structures and functions of tissues and organs. For example, researchers have used hydrogel-based materials to create scaffolds that can self-bend into curved structures, mimicking the natural shape of cartilage. These scaffolds can be used to grow bone cells, demonstrating the potential for 4D printing in creating multicellular cartilage tissue[1].

Biomedical Applications:

- Deployable Medical Devices: 4D printed stents and orthopedic implants can be designed to take on a compact shape during surgery and then deploy to their full size once in place, reducing the need for invasive procedures.

- Customized Implants: 4D materials can adapt to the changing needs of the body, such as vascular stents that change shape in response to blood flow or vessel diameter.

- Infection Prevention: 4D printed materials can be designed with complex surface nanopatterns that stimulate certain cells or kill bacteria, preventing infections upon implantation[1].

Architectural and Engineering Applications

Beyond biomedical applications, 4D printing is also transforming architectural and engineering design.

Adaptive Buildings and Structures

Imagine buildings that can adjust their facades in response to temperature and sunlight, or furniture that self-assembles when you take it home. These are not just concepts but real possibilities with 4D printing. Skylar Tibbits, an associate professor at MIT, has been a pioneer in this field, inspired by the shape-shifting properties of natural structures like the pinecone[1].

Architectural Innovations:

- Climate-Adaptive Facades: Buildings can be designed with 4D printed materials that expand, contract, or rotate in response to outdoor conditions.

- Self-Assembling Furniture: Flatpack furniture can be engineered to self-assemble when exposed to specific stimuli, making installation easier and more efficient.

- Dynamic Structures: Bridges and other infrastructure can be designed to change shape in response to environmental conditions, enhancing their durability and functionality[1].

The Role of AI and Machine Learning

The integration of AI and machine learning is further enhancing the capabilities of 4D printing.

Predictive Modeling and Simulation

AI can be used to predict the shape transformation of 4D materials and their physiological responses. This helps in guiding the selection of smart materials and ideal shape-shifting geometries during the design process. Additionally, AI can inform multi-material printing, where multiple smart materials with different stimuli are used in the same scaffold or construct[1].

AI-Driven Innovations:

- Predictive Analytics: AI models can predict how 4D materials will change shape and function over time.

- Real-Time Monitoring: The incorporation of sensors can provide real-time monitoring of 4D printed constructs, unlocking more functionality and ensuring optimal performance.

- Customized Designs: AI can help in designing customized 4D printed materials that respond specifically to the needs of individual patients or environments[1].

Practical Insights and Actionable Advice

For those interested in exploring 4D printing, here are some practical insights and actionable advice:

Choosing the Right Materials

When selecting materials for 4D printing, it is crucial to consider their biocompatibility, mechanical properties, and responsiveness to specific stimuli. Hydrogels, for instance, are highly biocompatible and can be tailored to respond to various environmental changes[2].

Material Selection Checklist:

- Biocompatibility: Ensure the material is safe for use in biological environments.

- Mechanical Properties: Choose materials with the desired mechanical properties, such as flexibility or rigidity.

- Stimulus Responsiveness: Select materials that can respond to the specific stimuli relevant to your application.

- Printing Compatibility: Ensure the material is compatible with the chosen 3D printing technique.

Designing for Dynamic Shape Changes

Designing 4D printed materials involves more than just creating a static structure. It requires understanding how the material will change over time and how it will interact with its environment.

Design Tips:

- Layer-by-Layer Construction: Use computer-aided design to construct complex 3D structures layer by layer.

- Multi-Material Printing: Use multiple smart materials with different stimuli to create complex, dynamic structures.

- Testing and Iteration: Test your designs under various conditions to ensure they perform as expected and iterate based on the results[2].

4D printing is not just a technology; it is a revolution in material science and engineering. With its ability to create smart, adaptive materials that change shape and function over time, it holds immense potential for transforming various fields. From biomedical engineering to architecture, 4D printing is opening doors to new possibilities and innovations.

As Amir Zadpoor, chaired professor of biomaterials and tissue biomechanics at Delft University of Technology, notes, “The initial configuration of these materials being flat creates many opportunities for adding surface-related functionalities, including complex nanopatterns and electronic devices.” This is just the beginning of what 4D printing can achieve, and as the technology continues to evolve, we can expect even more groundbreaking applications in the future[1].

Table: Comparison of Stimulus-Responsive Materials for 4D Printing

| Material Type | Stimulus Response | Applications |

|---|---|---|

| Shape Memory Polymers | Temperature, Light | Biomedical devices, self-healing materials, aerospace applications |

| Hydrogels | Humidity, pH, Temperature | Tissue engineering, drug delivery, biosensing |

| Liquid Crystal Elastomers | Light, Temperature | Soft robotics, adaptive wearable devices |

| Polymer Composites | Magnetism, Electricity | Medical devices, sensors, energy storage |

| Elastic Polymers | Pressure, Vibration | Soft actuators, dynamic structures |

Detailed Bullet Point List: Benefits of 4D Printing in Biomedical Applications

- Adaptability: 4D printed materials can adapt to the changing needs of the body, such as vascular stents that adjust to blood flow or vessel diameter.

- Minimally Invasive Procedures: 4D printed stents and orthopedic implants can be designed to deploy in place, reducing the need for invasive surgeries.

- Customization: Materials can be tailored to respond to specific physiological stimuli, making them highly customized for individual patients.

- Infection Prevention: 4D printed materials can be designed with surface nanopatterns that prevent bacterial growth and infection.

- Real-Time Monitoring: The integration of sensors allows for real-time monitoring of 4D printed constructs, ensuring optimal performance and safety.

- Biocompatibility: 4D printed materials, especially hydrogels, are highly biocompatible and can mimic the properties of natural tissues.

- Dynamic Shape Changes: Materials can change shape in response to external stimuli, mimicking the natural functions of tissues and organs.

- Multi-Material Printing: The use of multiple smart materials with different stimuli allows for the creation of complex, dynamic structures that can perform multiple functions.